Ensuring Only the Best

Demo Air Net is proud to give our stamp of approval to each and every one of our products. And we mean it - all of our filters go through rigorous quality control checks during and after the manufacturing process. This is to ensure their safety, endurance and ability to get the job done. If you have any questions about our process or want to speak with a service rep, please contact us today.

Operation Manual

Please take a moment, and let us explain this device to ensure you reach peak performance. The Demo Air Net was designed to meet the varied and often unpredictable needs of men and woman who work in an environment where airborne contaminates create a problem with health and safety. Unlike many forms of protection the filter is designed to both demonstrate its efficiency by visibly darkening as it captures the dust contaminate and be easily adaptable as the needs of the work place change.

It is important you have a clear understanding of how our device works, on a microscopic level. The level of airflow passing thru the filter is specifically designed not to disrupt airflow outside the filter wall. It has been proven that the intake of the assembly can capture dust along the outside walls of the filter as well. This is why we say the assembly clears in 360 degrees; therefore elevating the assembly off the ground is very important. The fabrics breathing rate is specific to maximize the rate of filtration, and is washable and yet retains its filtration characteristic.

After extensive testing, we realized that it is a very small setting which a particle of dust can be captured, yet allows airflow to persist. Lesser fabrics are cheaper, but won’t resist the expansion and contraction of washing and won’t trap all the varied airborne threats we filter out in high volume.

When you size the fan to be used, its CFM represents the exchange rate of air passing thru the fan. The higher the CFM the faster you approach outpacing the rate of contamination. Simply said you will see a point reached at which the filter keeps the air clean during work that is contaminating the space when properly sized, deployed. The key is the fan’s CFM, raise the ability of the fan, and you raise the rate of filtration.

In the following paragraphs you will learn the 9 secrets to unleashing the full potential of this device. You will also be instructed on cleaning, as well as the ideal operating conditions and how to obtain them.

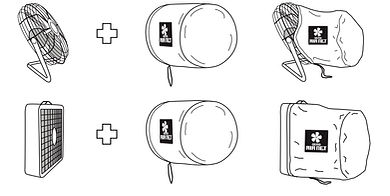

Attaching to the fan:

1. Shut off the fan. Remembering you will be strapping the filter to the discharge end of the fan.

2. Lay the fan on its back, intake side down.

3. The filter bungee cord is built to be kept tight. The bungee you can tie into a knot like your shoes, and leave it tied. Smaller versions have cord stops to assist in grabbing the fan cage.

4. Strap the filter to the fan, ensuring you are not blocking the intake.

5. You must ensure it is completely strapped all the way around the cage of the fan. Do not assume it is secure, start the fan and test the grip.

6. If the net blows off, you need to tighten the cord more, or ensure you are at the center point of the cage, completely around the cage.

7. REMEMBER TO STOP THE FAN BLADES COMPLETELY BEFORE REMOVING THE FILTER FOR CLEANING, OR TRANSPORTING.

WASHING

When you are done for the day, and you have exposed the Demo Air Net to dust, you need to wash it inside out on gentle, then air dry. Pre-rinsing is advised when severely contaminated, we use a bucket of clean water. Do not expose yourself or others to the dirty net, utilizing a plastic garbage bag so you can transport without risk. If shaken into waste container outdoors, to empty be aware of direction of prevailing winds.

If capturing highly toxic particulates, please follow Industry standards of disposal governing such dust. We simply air dry in 2 minutes...

WARNINGS:

-

DO NOT run the fan with a Demo Air Net if the fan is dirt from use or exposed to explosive or flammable Material.

-

Avoid the area between the Assembly Intake and the event. The level of deadly pollutants is highly concentrated in this Area. (THIS CONCENTRATED STREAM OF POLLUTANTS SHOULD NOT BE TAKEN LIGHTLY, AND CONSIDERED DANGEROUS AND TREATED AS SUCH)

-

NEVER Assume the fan and net assembly is secure. Test and ensure it’s secure and safe prior to stepping away.

-

NEVER SHUT DOWN THE ASSEMBLY PREMATURE FOR THE SYSTEM WILL CONTINUE TO TRAP FOR EASILY 1 HR AFTER OR BETTER AFTER WORK STOPS. AS YOU PREPARE TO SHUT DOWN WORK, IT WILL CONTINUE TO CATCH THE “LIGHTER THAN AIR” CARCINOGENS.

-

-

-

-

-

-

-

-

-

9 Key Points

-

Danger Zone Avoid front of fan, due to the high concentration of Pollutants. This is where we have witnessed streams of dust, in high volume

-

ELEVATE Raise off floor, to ensure 360 degrees of clearing. This device clears in 360 degrees, as if a ball that is a vacuum. This has been witnessed repeatedly.

-

DEPLOYMENT Deploy before work begins, and leave running as long as possible. The device will take control of the air in the room, and begin the filtration immediatly. You will notice the airspace in the room will be cleaner from the start.

-

PROXIMITY/AIMING The closer the Intake the more it catches, aiming toward target. Not to close at disrupt the intake.

-

STABLE AIR Reduce cross currents, close windows, vents, doors providing breezes. We want control of the air, for stable air is easier to take control of with our device.

-

BLADE SPEED Slow to Medium is usually sufficient. Remember these particles are light enough to float, so start slow and experiment with blade speeds.

-

CLEAN Mop sink for a slight cleaning, Machine Washed on “GENTLE” for 100% & AIR DRY.

-

LOADING Look for discoloration of the Thread Lines, and you’ll notice here first it turning black.

-

FACE MASK Always wear a Face Mask as well. We will filter most, but not all the pollutants. And greatly reduce the burden on the mask.