Seldom in “Safety” do I encounter a new safety product that I believe is so innovative and new that it can protect a worker from an illness (Dust & Silicosis, a lung cancer) and save their life; that I would go through the trouble of informing anyone, and everyone that I know, of the product.

It is a net system that fits on existing fans which captures contaminated air and virtually cleans it.

As a former OSHA Compliance Officer in North Carolina I would like to share this information with all that can use it to reduce the respiratory exposure to total dust, silica and other similar contaminates in the construction workplace. Exposure to crystalline silica dust can be associated with a number of debilitating and fatal diseases, such as silicosis, lung cancer, and immunologic disorders.

I met Mr. Patrick Sheehan, of JP Sheehan Construction Co., the inventor, due to flight weather conditions when our flights were canceled and redirected. He renovates buildings from the 1800's, which led to this product invention caused by the exposure to the coal dust that settled in the old ceilings, and the plaster they were built with, and the frequent failure of the facemask as well as keeping the dust off the skin. Additionally, the failures of the plastic wrap and duct tape to keep the dust out of clean areas and everything else.

Until now there has not been an “area” engineering control for total dust and silica that was effective and affordable. There are some products that work on the vacuum principle to control dust at the point of generation, or wet methods, but not for the whole area where other workers are also exposed.

We have known for years that workers in a typical concrete block and drywall operations can create environmental conditions that exceed the permissive exposure limits (PEL) for total dust and silica. The only protection to the worker has been personal protective equipment (PPE), the “Dust Mask” which many construction workers hate to use. There are also other trades (electricians, plumbers etc.) that are working in the same vicinity, many times without any PPE.

Additionally, workers in the manufacturing of the brick, block, and Portland cement type products can be exposed to the contaminants.

This evaluation revealed to me, that with proper application of the necessary Demo Air Net units, it is possible to maintain compliance with OSHA and MSHA respiratory hazard protection requirements and potentially below the Permissible Exposure Limits (PEL). The net captures large volumes of contaminated air keeping total dust and silica levels down, where only minimal PPE might be needed and protecting short-term workers that may enter the area.

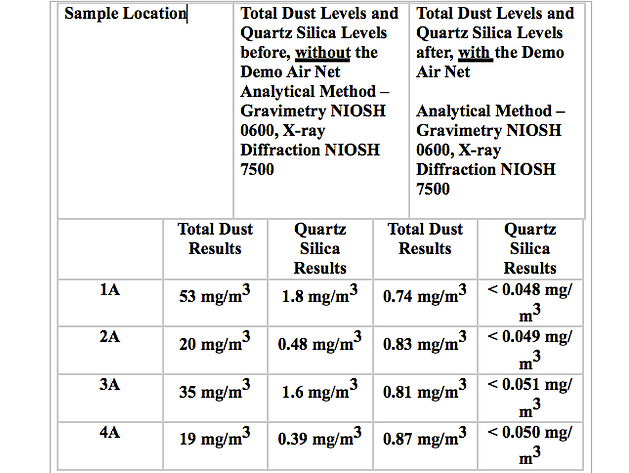

I invited Mr. Sheehan to bring his product to North Carolina for a demonstration of its capabilities. I had an air quality evaluation of the Demo Air Net conducted by Jill Warren & Associates (Industrial Hygienist) at a Hendrick Construction, Inc job site, a North Carolina OSHA Building Star (OSHA VPP) construction site. Jill Warren is also a former OSHA Health Compliance Officer. I wanted to see the effectiveness of the system. We were extremely surprise at the results and the visual clarity of the air in the room when using the Demo Air Net.

The air sampling was done in a 31,000 cubic foot room under construction. The room was composed of concrete block. One wall was lined with windows. The room had two standard size entrances. The outside entrance was equipped with a door that remained closed during the sampling periods. The other door, which leads to the inside of the building, was blocked and the ventilation system was closed off.

We purposefully contaminated the room. A medium fan was placed at the center of the room aimed upward. Construction waste (drywall, block, cement, etc.) dust (from an actual construction site) was liberated on top of the fan and blown upwards into the air. Two additional fans were positioned 5 feet on both sides of the center fan to keep the dust circulating throughout the room. Four air sampling units were placed around the center fan approximately 3 feet off the ground. Two samples were placed on either side of the fan at 12 feet from the fan. Two additional samples were placed 6 feet from the fan. A standard 42-inch diameter floor fan was used in the exercise with a Demo Air Net was installed.

Samples for Total Dust and Quartz Silica were collected using Air Check 52 air pumps equipped with a 5-micron polyvinyl chloride (PVC) filter cassettes attached to tygon tubing connected to the air pump. After completion of the sampling, the samples were sent to the laboratory where they were analyzed using Gravimetry NIOSH 500 for Total Dust and NIOSH 7500 for Quartz Silica.

Sample Location

Total Dust Levels and Quartz Silica Levels before, without the Demo Air Net

Analytical Method – Gravimetry NIOSH 0600, X-ray Diffraction NIOSH 7500

Total Dust Levels and Quartz Silica Levels after, with the Demo Air Net

Analytical Method – Gravimetry NIOSH 0600, X-ray Diffraction NIOSH 7500

The test revealed that an area where the respiratory hazards were out of compliance, the Demo Air Net was able to bring the room conditions into compliance with OSHA PEL levels and the silica level nearly undetectable.

We also learned that the use of the Demo Air Net units can reduce the final clean up time during punch-out of the new buildings before delivery to the client. The construction dust that is stirred during construction activities which normally settles on the rafters, trusses and pipes could be virtually eliminated. This reduces both time and cost of clean up and preparation for painting surfaces.

During remodeling of an existing business interior space, where the ventilation system of the building has to remain on, the Demo Air Net can control the air contaminants that many times escape into the clean areas and the duct-work of the existing ventilation system.

Although I do not currently work with Asbestos, I am certain that using the Demo Air Net in asbestos abatement operations will also produce a significant reduction of the air contaminants at the point where the Asbestos is disturbed into the air.

Also, sweeping towards the Demo Air Net can pick up some of the heavier dust particles that settled onto the floor.

There is no doubt in my opinion, that this invention is a method of engineering out the respiratory hazards in large open areas, and will help construction and remodeling companies to come into compliance with safety requirements.

As a former OSHA compliance officer, I see the use of Demo Air Net method of controlling Silica exposure, becoming as prevalent to construction, as the use of “wet-cutting” for brick, block and tile is today.

Remember that OSHA’s position is to engineer out the hazard first, before considering the use of personal protective equipment (PPE) to provide protection to the worker.

Additionally the workforce will enjoy a cleaner air environment to work in which is not normally possible under today’s work practices and saving time and money during final clean up.

Please pass this email to anyone that can benefit from the use of this product to protect his or her workers from the exposure to respiratory hazards such as, but not limited to, Silica.

Internet link, Demo Air Net at http://www.demoairnet.com/

Thanks – Mel Rosa

“YOUR SOURCE FOR OSHA COMPLIANCE”

SDOSB-DBE/MBE-HUBZONE

12216 Pinegate Court, Pineville, NC 28134

Phone: (704) 277-5673 Fax: (704) 900-8241 HYPERLINK "http://"

March 30, 2013

Michael Buchet Office of Construction Services Directorate of Construction USDOL-Occupational Safety and Health Administration 200 Constitution Ave., NW, Rm N3468 Washington, DC 20210

Dear Mr. Buchet:

I was asked to perform air monitoring to evaluate the effectiveness of the Demo Air Net. I was amazed at the results. The Demo Air Net system significantly reduced the dust levels in the testing area. The Demo Air Net is unique in that it can be attached to any fan exhaust and capture particulates down to 5 microns in size.

Another feature of the Demo Air Net relates to the dust collection system. Instead of the dust collecting on the surface of the Demo Air Net and ultimately reducing the fan efficiency, the material forms a ball inside the bag providing an obvious indicator of when the bag should be emptied.

A fan equipped with the Demo Air Net can be positioned anywhere to reduce employee exposure. In a situation where employees cut concrete, the fan can be placed so that it pulls the concrete dust (including silica) away from the employee’s breathing zone. The resulting dust is captured in the Demo Air Net, reducing the amount of dust in the work area and the amount of dust that will settle out.

Fine dust can be a real issue when employees are sanding dry wall. A fan equipped with the Demo Air Net can be positioned below the employee with the intake angled up toward the employee. This configuration will pull the dust down and away from the employee’s breathing zone into the Demo Air Net.

When portable ductwork is necessary, the Demo Air Net can be attached to the exhaust fan used with the portable ductwork to capture particulates instead of releasing them into the surrounding work area. This includes ventilators used to control dust levels in confined spaces such as storm drains and sewers during operations that require employees to cut or grind on concrete pipe.

A fan equipped with the Demo Air Net can be used to clean the construction area at the end of the day eliminating potential employee exposures created by employees walking through a dusty work area and stirring up the dust that has settled.

The applications of this product are endless. This product can have a huge impact on employee exposures to silica and other particulates in the construction industry and may reduce the occurrence of lung cancer, silicosis and other health problems associated with the inhalation of particulates.

Jill Warren

Industrial Hygiene Consultant

Warren & Associates

WARREN & ASSOCIATES

PO Box 2597 phone: (704) 841-4093

Matthews, NC 28106 email: warrenj3@windstream.net